In production, maintaining close watch over costs is essential to profitability. Proper spending begins with two important processes: purchasing and procurement. While these words are frequently used interchangeably, they play distinct roles. Purchasing satisfies short-term requirements by making materials and parts available for operations on a daily basis. Procurement, however, is the strategic function of choosing suppliers, reducing risks, and planning long-term expansion.

Recognizing these differences early enables businesses to manage costs, enhance efficiency, and create a more solid foundation for the future. Let’s learn these differences in detail.

What is Procurement?

Procurement in manufacturing is not just a matter of purchasing products. It is extensive market research, supplier choice, effective negotiation, and risk management. The objective is not just to get the best price but to create partnerships to facilitate ongoing innovation and supply chain robustness.

Important functions of procurement are:

- Market Research & Analysis: Systematic analysis of price trends, supplier capability, and price volatility.

- Supplier Identification & Selection: Establishing criteria to choose suppliers with the capability to deliver quality, innovation, and capacity.

- Negotiation & Contracting: Using best negotiation strategies and developing contracts that set clear expectations.

- Supplier Relationship Management: Building long-term relationships through regular performance review, feedback, and collaborative improvement initiatives.

- Risk Management & Compliance: Identifying risks in advance and ensuring compliance with regulatory standards and industry best practices.

What is Purchasing?

Purchasing, however, is a category of procurement that concentrates on the day-to-day operation of obtaining goods and services. It is the execution of day-to-day transactions to ensure smooth material flow into production. Purchasing in manufacturing plays an essential role in sustaining production schedules and costs by managing order placement, receipt, and payment in an efficient manner.

Important purchasing functions are:

- Requirement Identification: Identifying precise material and component requirements against production requirements.

- Order Placement: Placing orders correctly by verifying specifications, quantities, and delivery schedules.

- Order Fulfillment & Delivery Tracking: Managing the logistics process for timely delivery and quality control.

- Invoice Processing & Payment: Correctly verifying and processing invoices and coordinating with accounting systems.

- Record Keeping & Performance Review: Maintaining records to track performance and determine areas of process improvement.

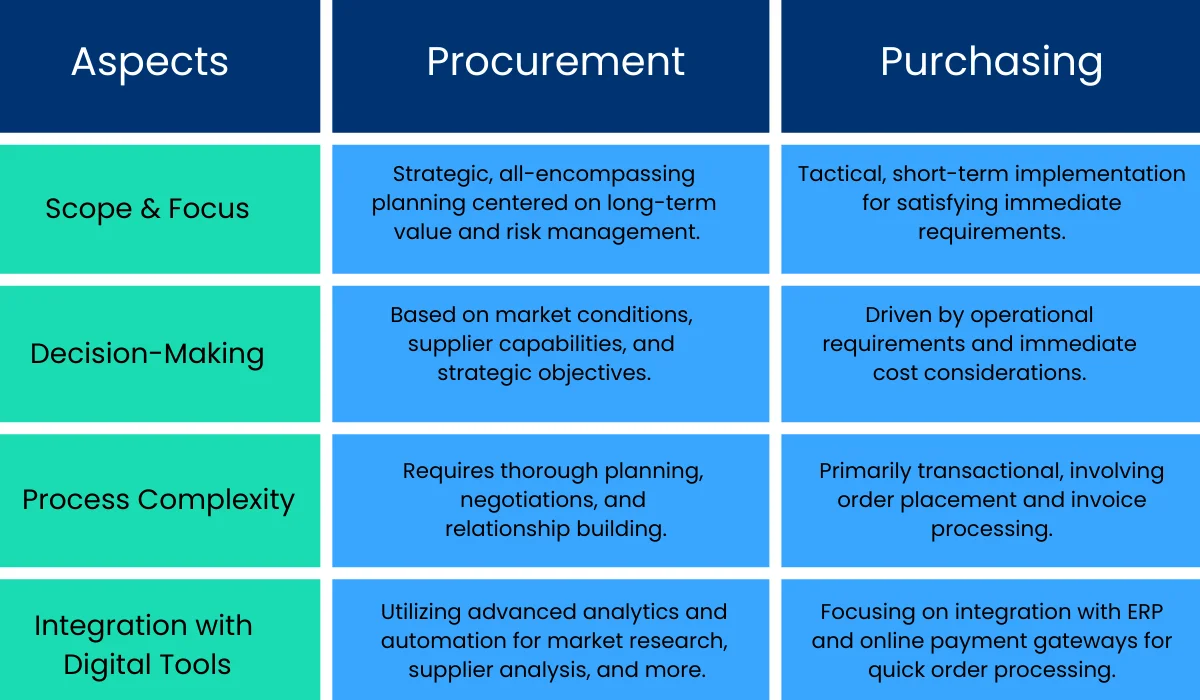

Comparative Analysis: Procurement vs. Purchasing

The distinction between procurement and purchasing is fundamental to building an effective supply chain. Below is a side-by-side comparison:

For manufacturing businesses, aligning both functions is key. Strategic procurement lays the groundwork for supplier partnerships and long-term savings, while efficient purchasing ensures production continuity through seamless transaction processing.

Why It Matters – The Business Impact

The difference between purchasing and procurement immediately affects a firm’s operational effectiveness, cost management, and competitive advantage.

1. Cost Savings & Efficiency

While major corporations have gradually incorporated digital tools into their processes, smaller firms are soon catching up, which indicates a significant change in new trends in procurement. Data management, sophisticated digitalization, risk avoidance, and efficient contract lifecycle management are areas that are being spotlighted among such enterprises.

These factors are crucial in creating a procurement environment that’s not just highly digitalized but also solid and agile to cope with the continuously changing business landscape.

As organizations set their sights on these ambitious digital targets, it’s evident that procurement is set for a major overhaul that will redefine its role within the corporate world and drive lasting, impactful change.

2. Risk Management

Procurement’s risk assessment and management of suppliers are crucial for determining whether or not there are likely supply chain disruptions. Including contingency planning and thorough supplier reviews allows businesses to manage risks related to market risk, changes in regulation, and geopolitical risks.

Purchasing complements this by ensuring that any near-term issues are rapidly found and addressed through proper order management.

3. Innovation & Growth

Procurement strategically enables innovation. Production firms can integrate new technologies and processes that ensure product innovation and operational effectiveness when dealing closely with suppliers.

In the process, suppliers sometimes collaborate on innovation, sharing ideas to help firms remain competitive. The purchasing ensures that the innovations are introduced harmoniously onto the shop floor through effective management of day-to-day transactions.

4. Digital Transformation and Payment Automation

Newer supply chains heavily depend on technological tools to be more efficient. Automated purchasing in the form of integrated ERP and electronic payment solutions minimizes errors and accelerates the order-to-payment process.

Digital procurement encompasses sophisticated analytics for market prediction, automated risk calculations, and real-time supplier performance monitoring. These technologies collectively result in a more responsive and agile supply chain.

Best Practices for Integrating Procurement and Purchasing Strategies

Integrating procurement and purchasing functions is critical for manufacturing firms to maximize supply chain performance. The following are the most important strategies for integrating these functions:

1. Integrative Approach

- Cross-Functional Collaboration: Create frequent meetings between procurement and purchasing teams to align on strategic objectives and operational requirements. A common approach facilitates the conversion of long-term goals into practical day-to-day processes.

- Unified Performance Measures: Create complete KPIs that reflect strategic and transactional performance. Measurements could be supplier reliability, order accuracy, and cost savings through contracted agreements.

2. Utilizing Technology

- Integrated Software Solutions: Implement procurement management software that integrates with ERP and accounts payable software. Integration enables real-time data exchange, automated order tracking, and streamlined invoice processing.

- Data-Driven Decision Making: Leverage analytics to track market trends, supplier performance, and process inefficiencies. Data-driven insights enable teams to make better-informed decisions that improve strategic and transactional purchasing.

3. Continuous Training and Improvement

- Ongoing Education: Invest in training programs that keep procurement and purchasing teams current on industry trends, regulatory updates, and new digital tools.

- Feedback Mechanisms: Establish communication channels for timely feedback from the internal stakeholders and suppliers. Continual performance measurement and free communications promote continuous improvements in both functions.

4. Digital Payment Integration

- Automation in Payment Processing: Embrace digital payment systems that digitize invoice checking and payment settlement. Automation simplifies manual processing, reduces human errors, and enhances the effectiveness of the overall purchasing process.

- Seamless Integration with Financial Systems: Make sure payment solutions are integrated completely with your firm’s financial and ERP systems. This integration gives a complete picture of financial performance, improves budgeting accuracy, and aids strategic procurement decisions.

Conclusion

In the current competitive manufacturing landscape, it is crucial to distinguish between procurement and purchasing clearly. Procurement creates a strategic context through thorough market research, supplier analysis, and risk mitigation, while purchasing facilitates smooth day-to-day business. Digital technologies and payment automation further buttress these processes by minimizing errors and automating routine tasks.

By aligning these functions, businesses can lock in long-term supplier relationships, gain cost savings, and reduce operational risks. In the end, combining strategic procurement with effective purchasing practices forms the basis of a robust and flexible supply chain, setting businesses up for long-term success in an ever-changing market.